Magnetic stripe as a design feature of plastic cards

Now, more than ever, companies want to differentiate from their competitors by establishing a strong corporate image and ensuring brand equity. Resilient organizations use these concepts to convey clear directions and goals, help protect the company’s reputation and create a sense of belonging for employees. In addition, the strong corporate image and brand have aroused public resonance and loyalty.

Plastic cards have always been an excellent tool for communicating with internal and external customers to increase brand awareness and loyalty. Regardless of how many new developments have emerged in the digitalization of payment, loyalty programs and identification, plastic cards are and will continue to be the preferred method for customers and issuers.

However, it is a challenge to design a plastic card to convey the company's identity and brand value of the issuing bank in a plastic material of 3×3/8 inches×2 1/8 inches. Card designers and card manufacturers need to be consistent with brand image guidelines and ensure that the design follows the latest trends while maintaining a balance of time, cost and quality.

Previously, the only way to extract brand value from the magnetic stripe area of a plastic card was to use its color, but Pantone® color matching can be expensive and time-consuming, so this option is less attractive for small and medium production runs. .

Fortunately, there are many new options to win real estate on the card, such as using a magnetic strip as a design feature. In this article, we explored three innovative alternatives.

"Bleeding" effect

A new design trend is to make the magnetic stripe on the edge of the card "ooze". Several well-known brands have explored this design, which has won widespread recognition from customers.

For this, use a magnetic strip that is wider than a standard magnetic strip (usually between 14.3mm and 16mm). This design fully complies with the current card manufacturing specifications, and the card can be encoded using traditional magnetic tracks and can be read by any standard equipment.

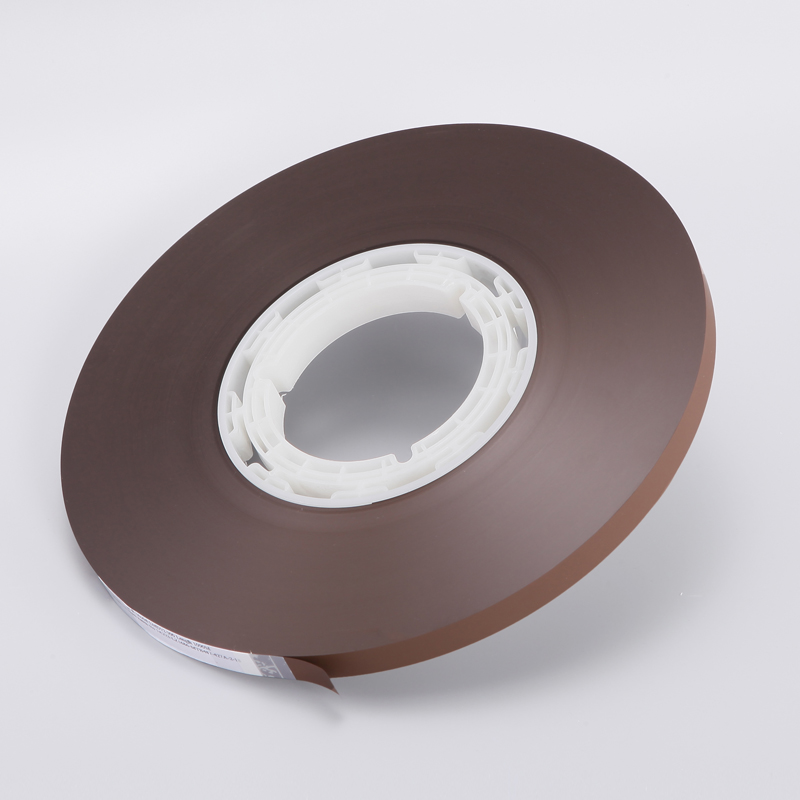

In addition, this wide magnetic stripe can have any color imaginable. In cooperation with tape manufacturers, these types of magnetic strips can be purchased in traditional or Pantone® matching colors for greater impact.

By purchasing these wide magnetic strips that have been pre-laid on the overlay, card manufacturers can produce very fast turnover cards for their customers, regardless of the number.

Hidden magnetic stripe

In Asia (especially in Japan), hidden magnetic stripes have been used for several years. However, from intellectual property to practicality of production, its implementation in other parts of the world has encountered many obstacles. But no longer.

Card manufacturers can now use cover paper that has been pre-laminated with a hidden magnetic stripe and primed, can be overprinted, and then sorted for lamination as usual.

This option provides complete design freedom, because the magnetic stripe can be overprinted without losing its function. Card manufacturers can imitate wide magnetic stripes, customize color magnetic stripes or completely cover magnetic stripes to achieve a completely hidden design. The design possibilities are endless.

A fully validated and tested manufacturing method to ensure that the magnetic strip maintains its recording and reading functions, making this option suitable for any kind of plastic card application. Membership programs, access control and financial cards will always maintain their performance requirements for coding and readability.

After overprinting the pre-laminated and pre-backed paper, the card manufacturer can use its current process for finishing. No further modification of the production process is required.

The hidden magnetic stripe is very suitable for small batch production and complex designs.

Holographic effect using laminate

To add distinction and perhaps additional security features, some card issuers considered using holographic tapes, but quickly gave up when faced with the reality of cost, minimum order quantity, and delivery time.

By using specially designed laminates, card manufacturers can add logos or text during lamination and emboss them onto the magnetic strip to provide holographic (dynamic light reflection) functionality.

This process is more cost-effective and time efficient than purchasing specially designed holographic tapes, and provides unique anti-counterfeiting features for any number of production activities.